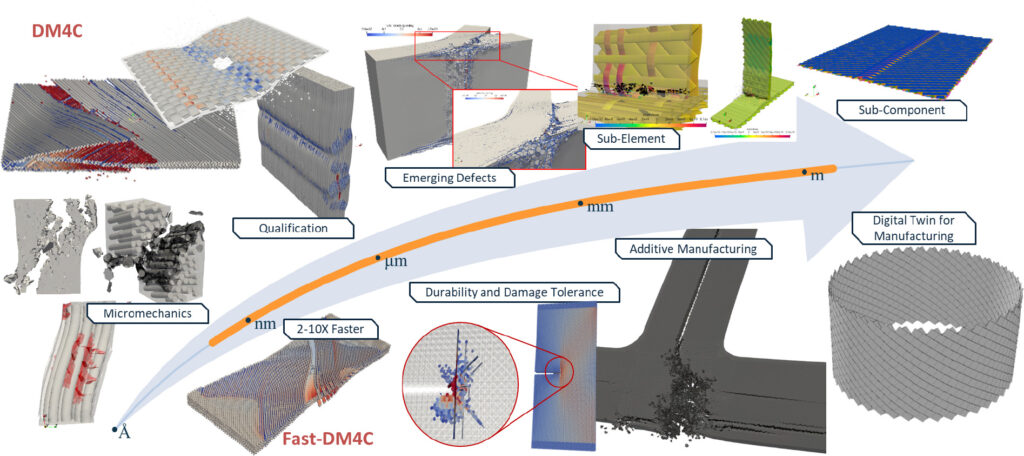

Aerospace Applications

The Discrete Model for Composites (DM4C) and its advanced extension, Fast-DM4C, represent a significant advancement in the computational modeling of complex, highly heterogeneous composite materials. As an extension of the Lattice Discrete Particle Method (LDPM), DM4C is specifically tailored for these materials. The explicit use of Timoshenko Beams to represent the material’s structural elements offers both computational efficiency and dexterity for solving problems across the multiscale paradigm. This efficiency facilitates simulations that effectively account for hundreds to thousands of individual fibers, “superfibers” (conceptual aggregations of multiple fibers), or larger structural units such as tows and rasters. This innovative approach enables DM4C and Fast-DM4C to accurately represent and simulate a wide array of composite architectures, including individual lamina, intricate laminate structures, various textile composites, and materials produced through additive manufacturing processes. This multi-scale capability is critical for a comprehensive understanding of composite material behavior, encompassing initial material design and optimization, prediction of failure mechanisms, and overall structural integrity seen in Aerospace applications.

Microstructual Response

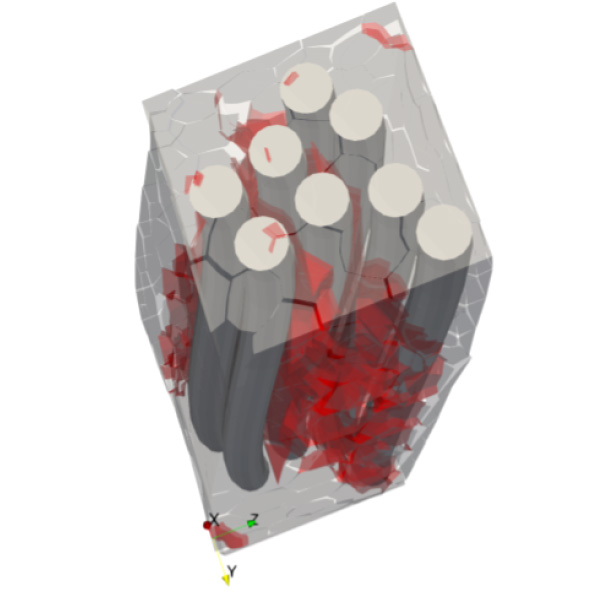

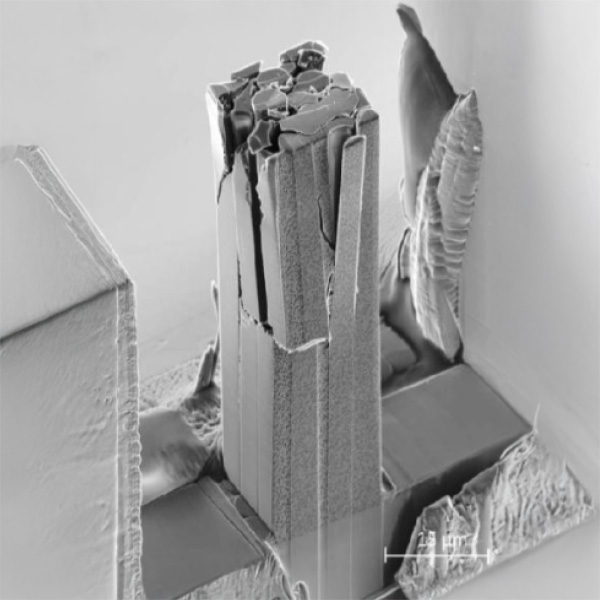

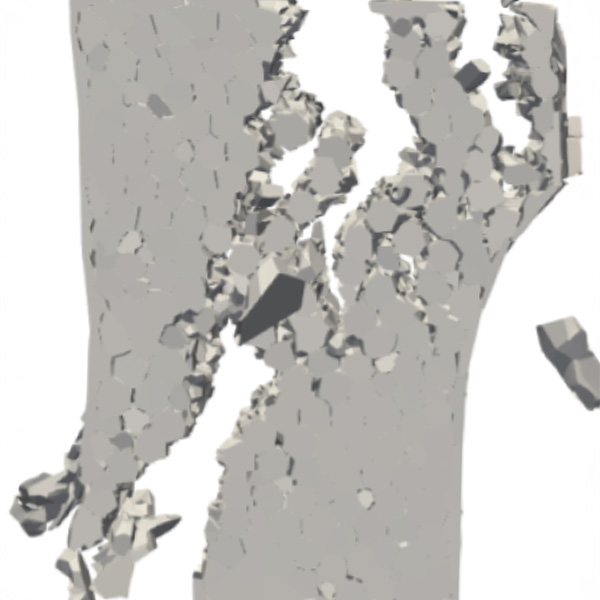

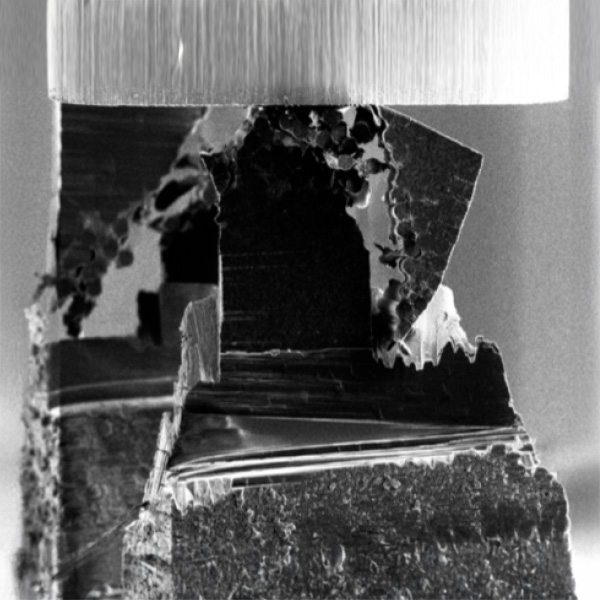

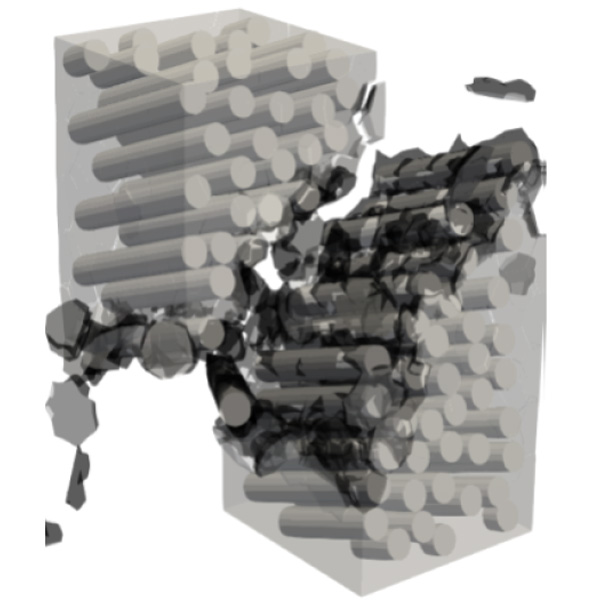

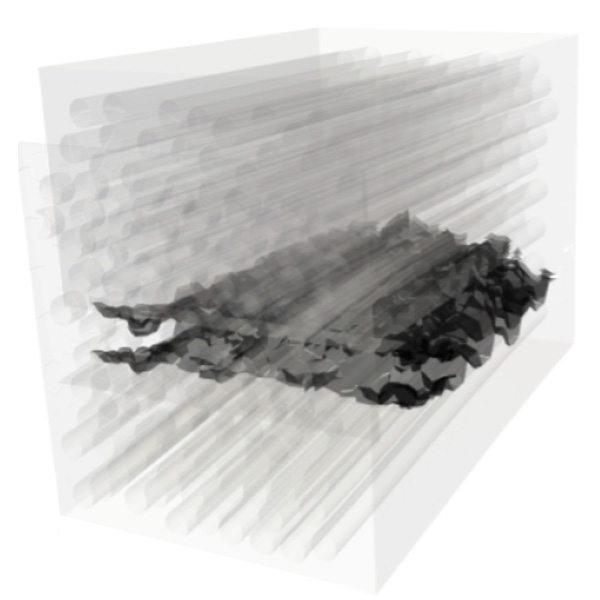

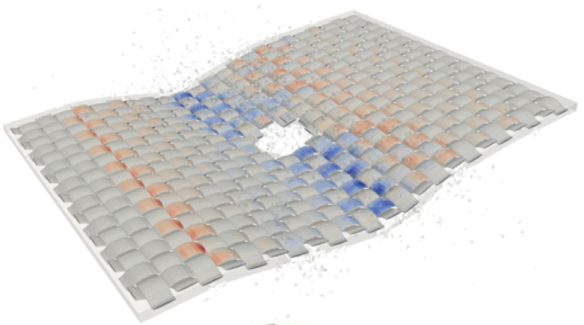

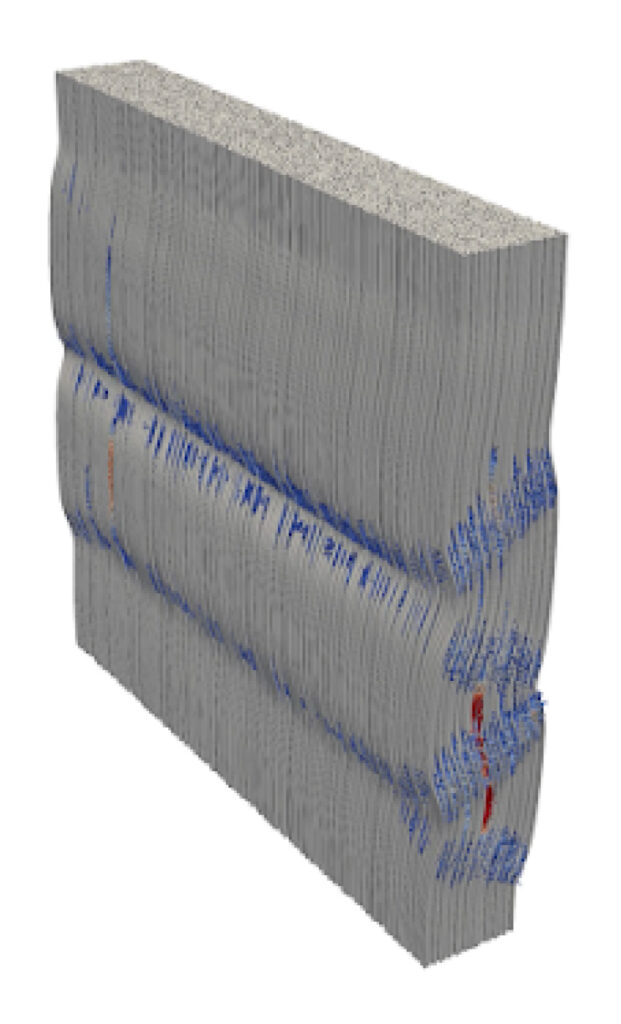

DM4C represents a significant advancement in the field of composite materials science, offering an elegant and remarkably efficient methodology for predicting microstructural responses at an unprecedented microscale resolution. This innovative approach distinguishes itself from conventional continuum-based models by its capacity to simulate the behavior of hundreds of individual fibers within a composite material. This expanded simulation capability allows for a far more comprehensive and accurate forecast of fiber distribution failure, even under a wide array of complex and challenging stress states, including the critical consideration of material instabilities.

The power of DM4C is vividly illustrated through its application in analyzing the failure of a lamina composite thermoset. As depicted in the accompanying figures, DM4C precisely models the intricate failure mechanisms of a material characterized by a 5.2-micron fiber diameter, specifically under compressive loading conditions. This detailed visualization and analysis are crucial for understanding the nuanced ways in which composite materials fail at the micro-level.

A cornerstone of DM4C’s credibility lies in its rigorous validation against experimental data. Every figure and simulation generated by DM4C has undergone thorough comparison and verification with real-world experimental results. This commitment to empirical validation ensures the reliability and accuracy of DM4C’s predictions, making it a robust and trustworthy tool for researchers and engineers alike in the design and analysis of advanced composite materials.

Composite Textiles

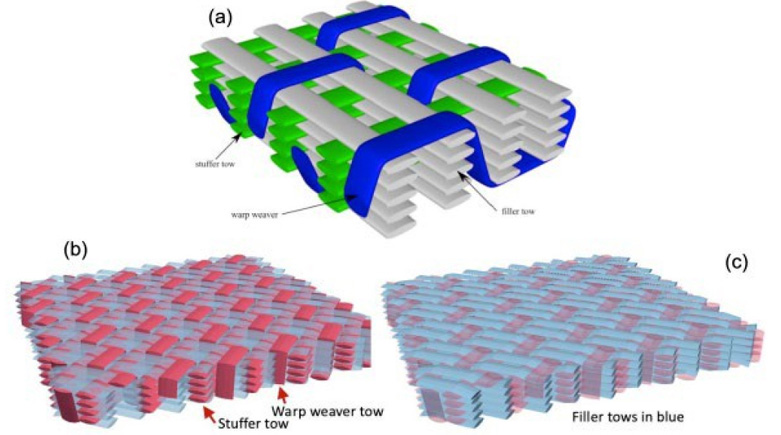

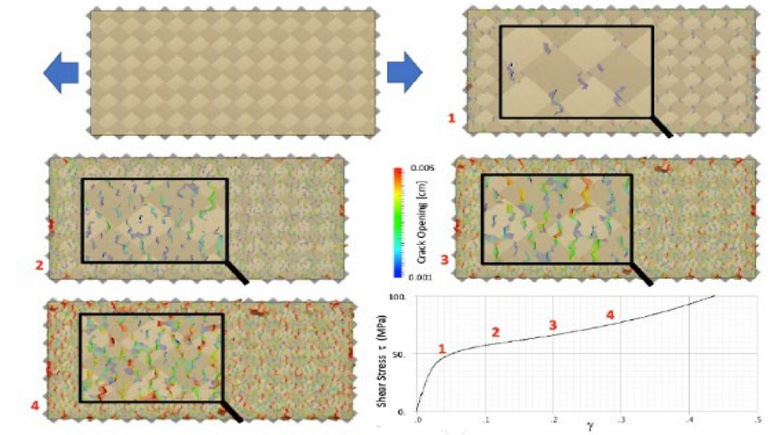

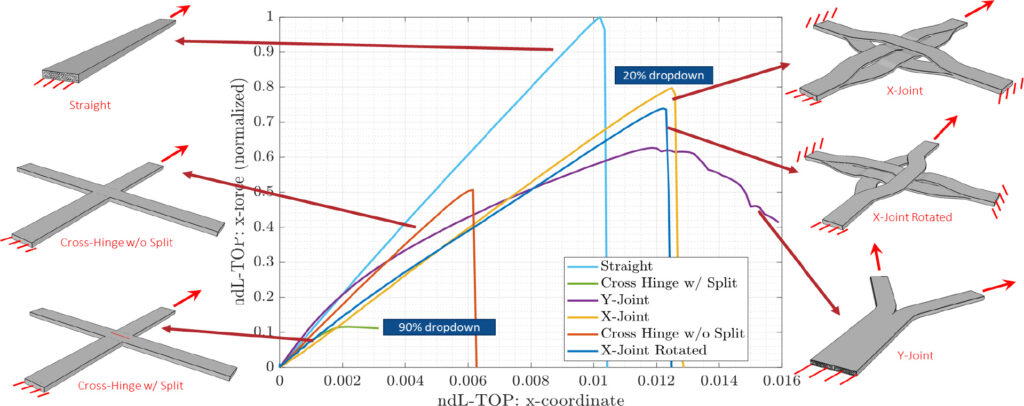

ES3’s DM4C approach utilizes Timoshenko beam elements to represent individual tows, which offers an efficient and versatile method for predicting the damage response of a wide range of textile fabrics, from simple plain weaves to complex 3D orthogonal architectures. This model’s strength lies in its ability to capture the complex interactions between intersecting tows, including bending, shear, and tension, which are crucial for understanding damage initiation and propagation. By discretizing the fabric into its fundamental constituents, the model can simulate the progressive failure of individual tows and the subsequent redistribution of loads, providing a detailed and accurate prediction of the material’s overall response to mechanical loading. This approach not only reduces computational costs compared to continuum-based methods but also provides a more direct and intuitive understanding of the underlying damage mechanisms in these composite materials.

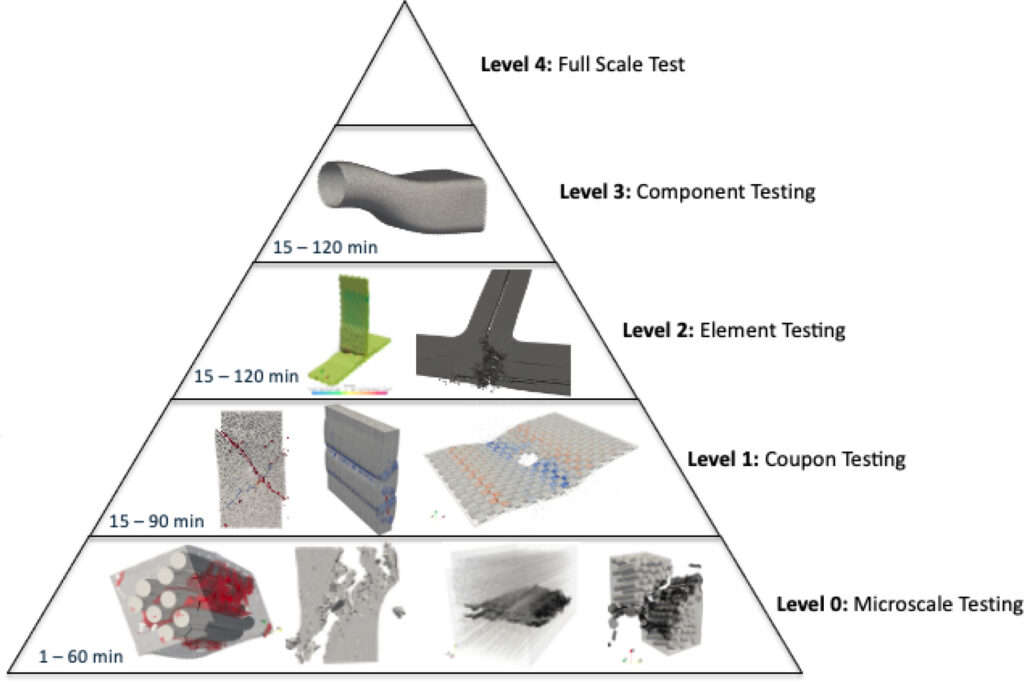

Qualification and Certification

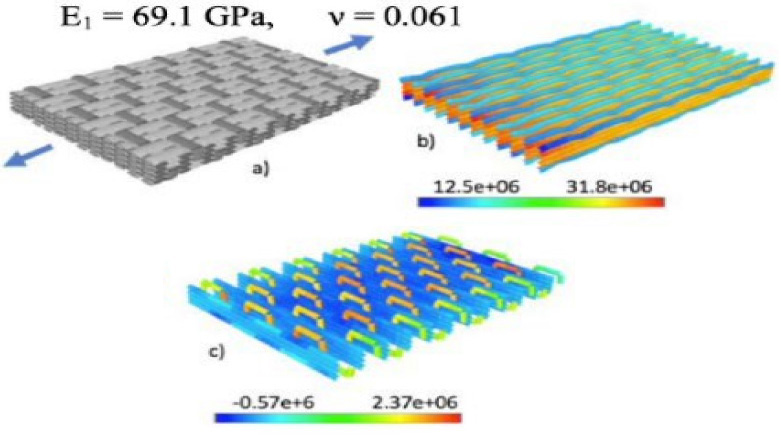

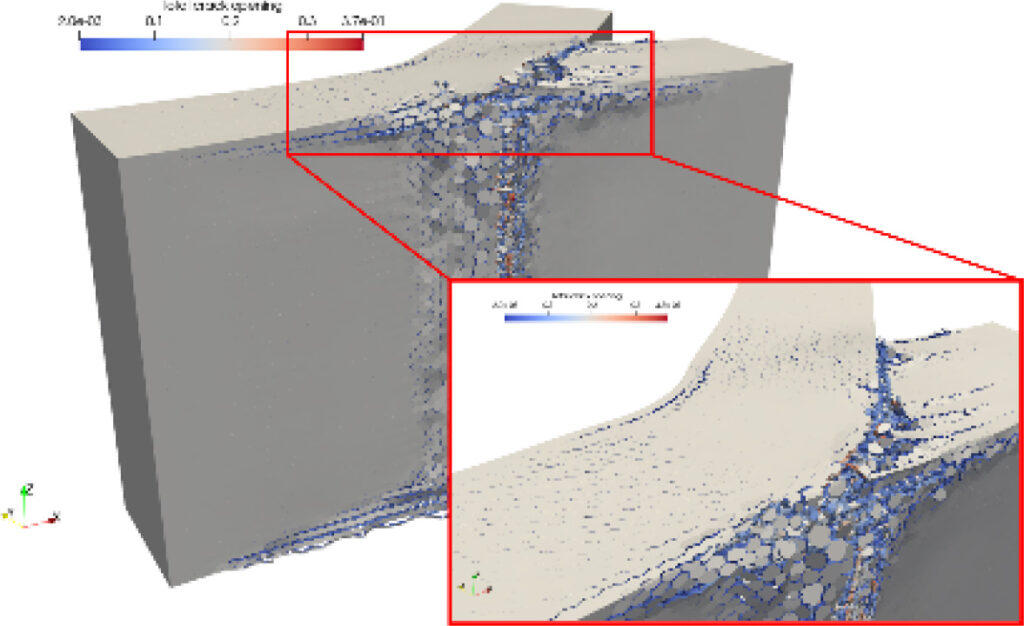

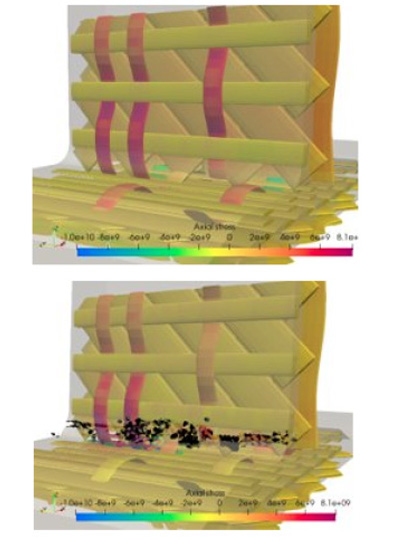

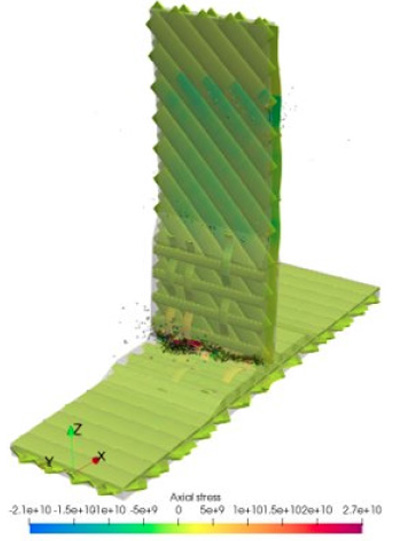

The advent of advanced computational tools like MARS and its DM4C module is revolutionizing the material qualification process for composite structures in aerospace. By explicitly simulating composite fiber deposition and matrix polymerization, DM4C generates ultra-high-fidelity models that precisely mirror the physical composition of the material at the mesoscale level. This unparalleled level of detail allows for the accurate prediction of fundamental failure mechanisms, such as ultimate crack failure in transverse compression and kink band formation in longitudinal compression, which are notoriously difficult to capture with traditional methods.

These sophisticated computational simulations empower engineers to understand and predict a composite’s behavior with unprecedented accuracy. By gaining deep insights into how damage initiates and propagates at the mesoscale, ES3 can significantly reduce the reliance on extensive physical testing. This not only dramatically cuts down on development and manufacturing lead times and costs but also accelerates the introduction of innovative composite materials, ultimately leading to increased aircraft range, strength, and safety for the future fleet.

Emergent Defects

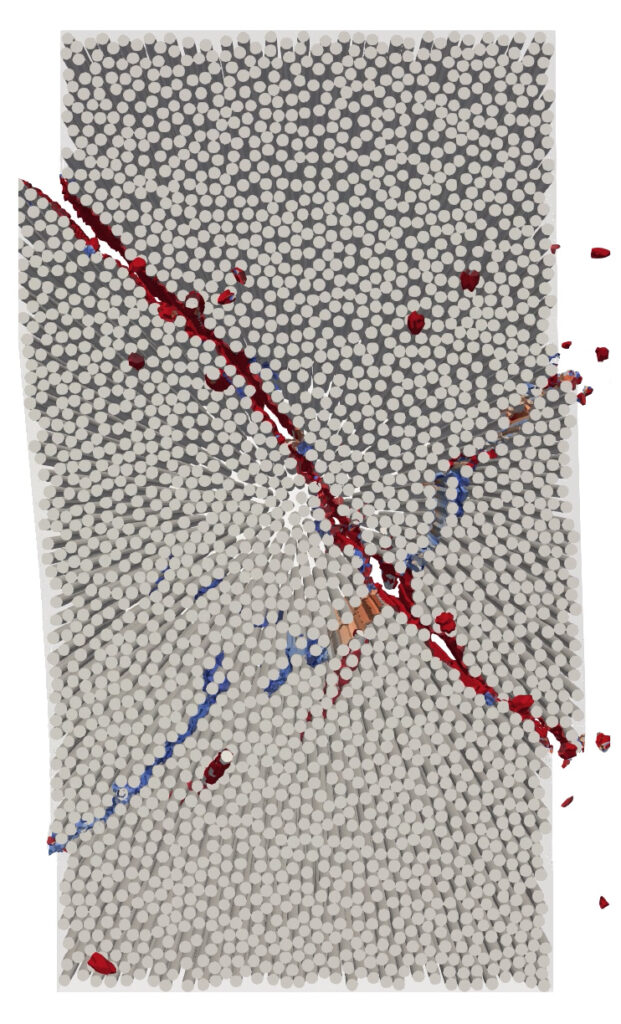

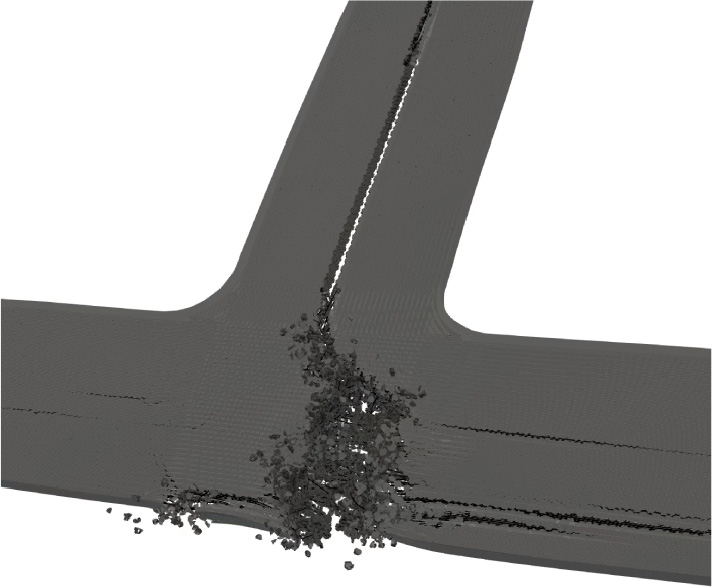

Emergent defects are hidden flaws that arise during the manufacturing process, often leading to structural weaknesses and potential failure. These defects are particularly relevant in additive manufacturing (AM), or 3D printing, where the layer-by-layer creation of a part can introduce unique imperfections. Unlike traditional defects that are easily identified, emergent defects are more subtle and can be a significant concern for the long-term reliability and safety of a part.

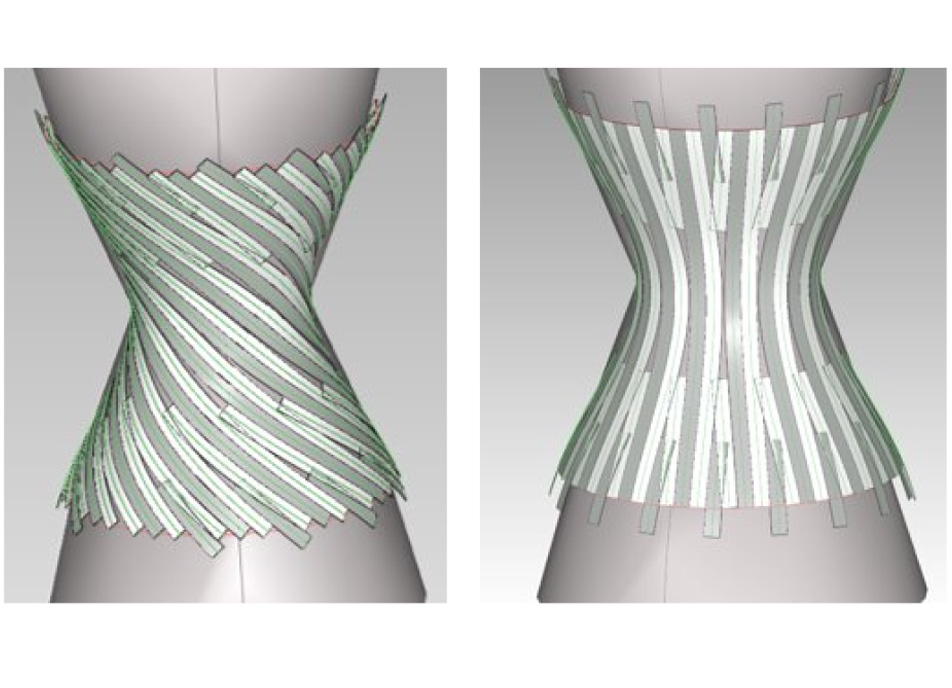

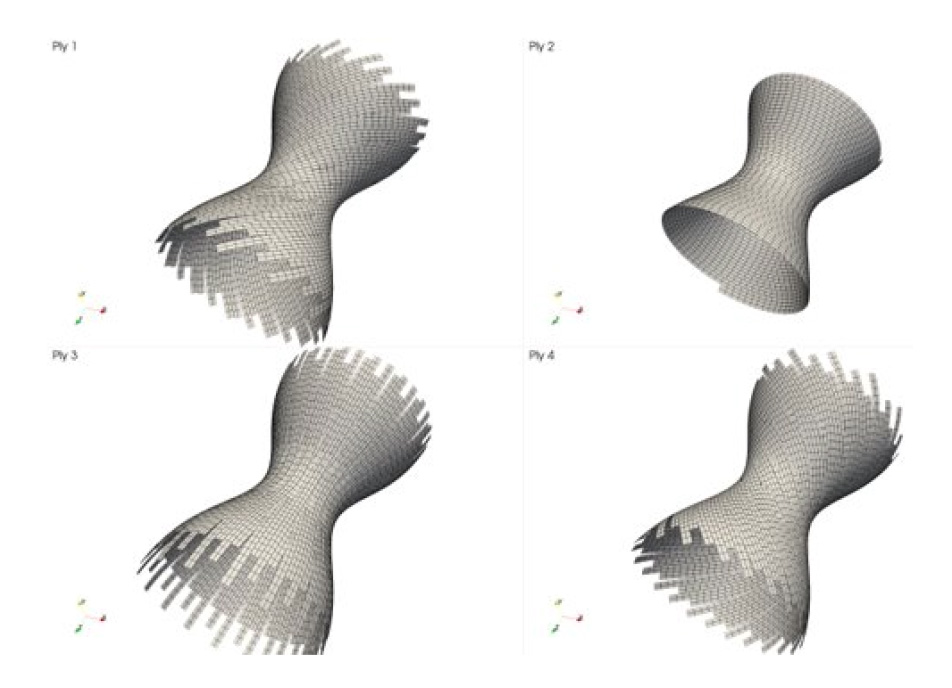

In additively manufactured parts, especially those made from composite materials, emergent defects can stem from a variety of sources. The way individual tows (bundles of fibers) are cut, placed, and bonded can create microscopic inconsistencies. For example, if a tow isn’t steered correctly, it can leave a small void or a weak interface between layers. This seemingly minor issue can become a failure initiation site, where stress concentrates and a crack can begin to form under load. This is especially true for parts designed for high-stress applications, such as aerospace components or medical implants.

The good news is that we can predict and mitigate these defects before they even occur. By using computational modeling and simulation, manufacturers can analyze the intended print pattern and predict potential weak spots. These models can simulate how the tows will be laid down, how different print paths will affect fiber alignment, and where stress concentrations might occur.

This predictive approach allows for a powerful optimization strategy. The print path—the specific sequence and direction of the printing head—can be adjusted to ensure that the composite structure is as strong as possible. For a given application, with a specific design limit load (the maximum load the part is expected to withstand without permanent deformation), the print path can be optimized to meet or exceed that requirement. This proactive approach ensures that the final part is not only free of emergent defects but is also engineered for optimal performance and durability.

Durability and Damage Tolerance

ES3 is committed to providing comprehensive solutions for understanding the durability and damage tolerance of advanced material systems, crucial for the aerospace industry. Our expertise spans from characterizing the intricate fracture process zone to modeling complex intra- and interlaminar fracture behaviors. We possess the methodologies to accurately simulate critical scenarios such as impact events, and to predict residual compression strength after impact, ensuring the structural integrity of components under various loading conditions. Furthermore, our dedicated team is actively developing advanced fatigue models specifically tailored for these materials, allowing for a more precise prediction of their long-term performance.

Our overarching goal is to integrate these sophisticated models into a robust probabilistic framework. This framework enables us to establish appropriate lifing terms for any given application, adhering to stringent industry standards like MIL-HDBK-1530D, “Aircraft Structural Integrity Program (ASIP),” and other relevant specifications for durability and damage tolerance. By providing a thorough understanding of material behavior under service loads and potential damage scenarios, ES3 empowers our clients to make informed design decisions, optimize maintenance schedules, and ultimately enhance the safety and longevity of their aircraft fleets.

Sub-element

In evaluating the sub-element part of the building block approach for a composite pi-joint, ES3 can assess the complicated fabric architecture by leveraging the predictive capabilities of a model like DM4C. This involves meticulously characterizing the ply lay-up, fiber orientations, and resin distribution within the pi-joint’s intricate fabric. By integrating this detailed architectural data into DM4C, ES3 can simulate the initiation and growth of various failure mechanisms, such as delamination, fiber fracture, and matrix cracking, at a localized level. The model’s ability to capture these complex failure modes, including the interaction of fasteners and z-pins, allows us to understand how the fabric architecture directly influences the sub-element’s response to applied loads, thereby validating the building block approach’s accuracy in predicting overall structural behavior.

Sub-Component

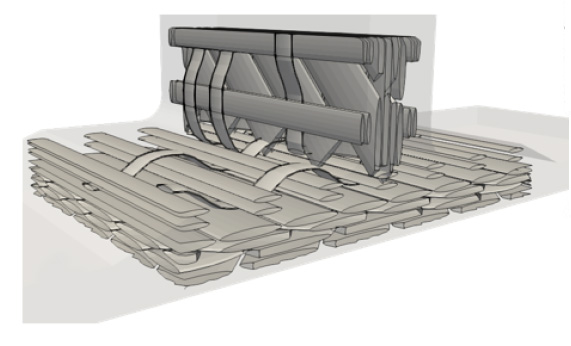

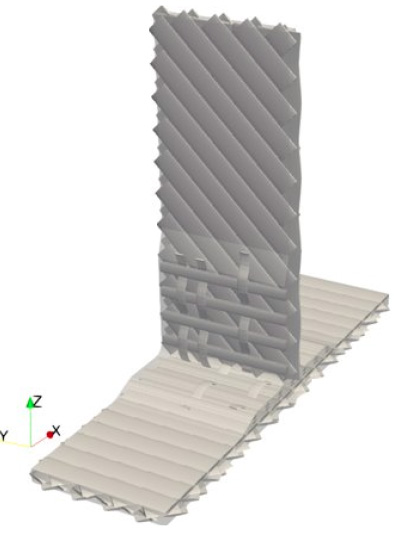

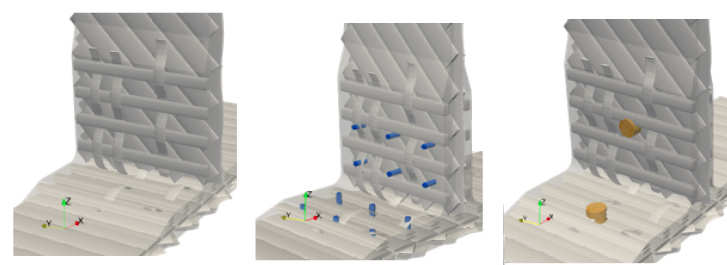

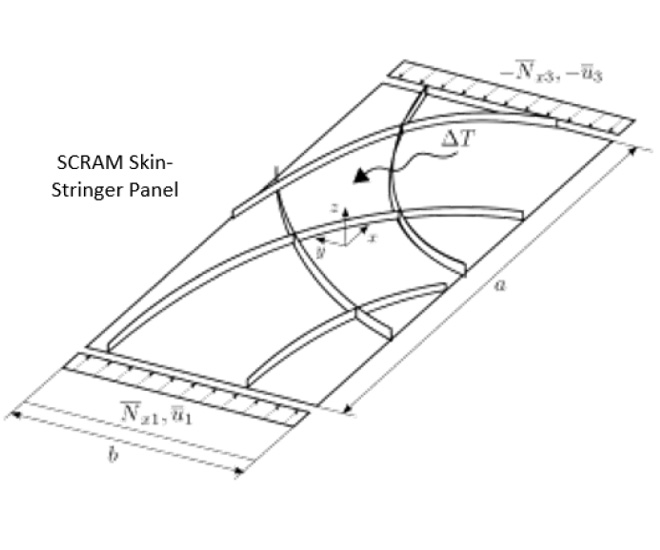

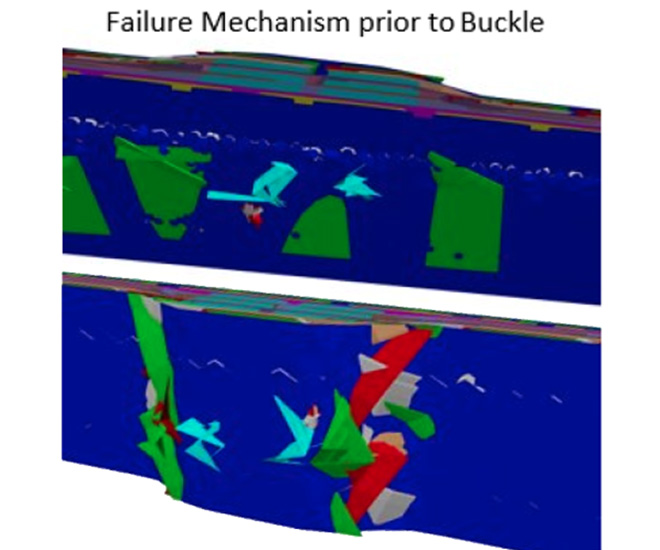

To accurately assess sub-component level complexity within a stiffened composite panel, our digital twin approach, powered by DM4C, is indispensable. This model uniquely captures the intricate interplay of geometric imperfections and manufacturing defects inherent in additive manufacturing processes, which are critical drivers of localized failure. By simulating mechanisms like matrix cracking and tow failure prior to buckling, DM4C allows for a granular understanding of how microscopic flaws propagate and coalesce, leading to sub-component degradation. This high-fidelity simulation provides unparalleled insight into the complex stress states and damage evolution at the most fundamental levels of the composite structure, ultimately enabling proactive maintenance strategies and accelerating the development of robust designs for future aircraft fleets.

Digital Twin

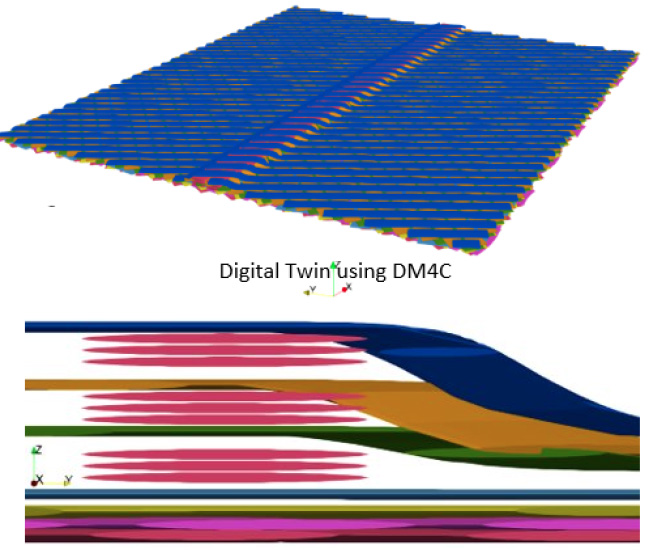

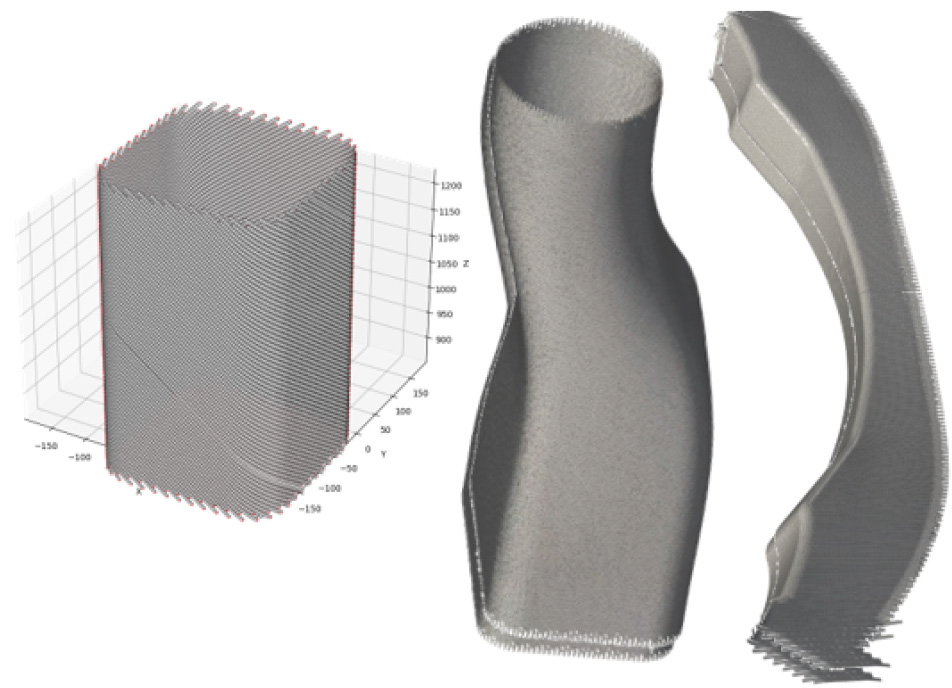

A digital twin is a virtual, real-time representation of a physical object or system. It’s a powerful tool that uses data to simulate, monitor, and analyze a physical counterpart throughout its lifecycle. For continuous fiber additive manufacturing (CFAM), where strength and integrity are paramount, a digital twin is essential. It enables a direct link between the design, manufacturing, and maintenance of a part.

Tools like DM4C are designed to make this digital twin concept a reality. DM4C acts as the hub of this ecosystem, allowing for the performance evaluation of the digital twin. By analyzing the data captured during the manufacturing process, it can simulate how the part will behave under various loads and conditions. This allows engineers to identify potential failure points and optimize the design before the part is even printed.

DM4C specifically uses the G-code, the machine language that controls the printer, to build a digital twin of the component. The G-code provides a precise record of the actual printed path, which may deviate slightly from the ideal design. By analyzing this G-code, DM4C can create a high-fidelity virtual representation of the “as-built” part, not just the “as-designed” part. This is crucial for assessing fracture of components, especially large ones, as it accounts for real-world manufacturing variables that could lead to defects.

By leveraging these tools, manufacturers can ensure that their CFAM parts meet the required performance standards, reducing the risk of failure and enabling a more efficient and reliable manufacturing process.

Building Block Approach: Everything is a Structure

ES3’s foundational discrete model for composites (DM4C) operates on the principle that any structure is a series of interconnected building blocks, from the smallest to the largest scale. This approach, rooted in fracture mechanics, allows for the accurate simulation of failure in structures of any size, from the intricate details of a micro-fiber to a complete aircraft component. By modeling individual fibers, super fibers, rasters, and tows, ES3 provides a powerful solution for the immediate and future needs of the aerospace industry, addressing challenges from the sustainment of Group 3-5 and manned aircraft to the design of next-generation aerospace vehicles. The software’s efficiency is a key strength; while some problems are solved in minutes on a standard laptop, others requiring high-performance computing are still handled with exceptional speed. ES3’s goal is to provide efficient solutions for modeling the fracture of any structure, regardless of its size or complexity.